If you’re designing a kitchen or bathroom, one of the most important features you’ll decide on is the countertops. It can be a daunting process, especially if you’ve never done it before. We put together this countertop buying guide to help you understand how the process works. Each fabricator might do things a little differently, but in general, this is what you can expect.

Step 1: Prepare & Plan

Get Your Cabinet Plans.

If you’re purchasing new cabinetry you should be able to get a copy of this from your cabinet installer. If you’re keeping existing cabinets, make a drawing showing the layout of the counters with approximate measurements. Include where walls and appliances are.

Gather Samples.

Find samples of any elements you would like your cabinets to coordinate with. We recommend focusing on anything that will be in direct contact with the cabinets, such as cabinets and backsplashes. You could also include paint, flooring, or tile samples. This is a good time to do some research on the overall style/color countertop you’d like for your space.

Note the Needs of Your Space.

Taking a moment to think about the needs of your space will help you make decisions when you visit a showroom. Consider how much wear and tear these countertops will be exposed to and the level of maintenance you’re willing to do.

Step 2: Visit a Local Showroom or Slab Yard

- When you arrive, find an employee to talk to about your project. Share all of your materials from step one so they can best advise you.

- Decide what type of stone you’re interested in looking at. Natural stone, such as granite, quartzite, limestone, travertine, and marble or engineered stone (quartz). Your fabricator will be happy to go over the pros and cons of each type if you’re not sure what will work best.

- When looking at Natural Stones…

- Keep in mind that slabs are cut in bundles. Slabs from the same bundle match in color and pattern, while slabs from different bundles can have a subtle variation or look dramatically different.

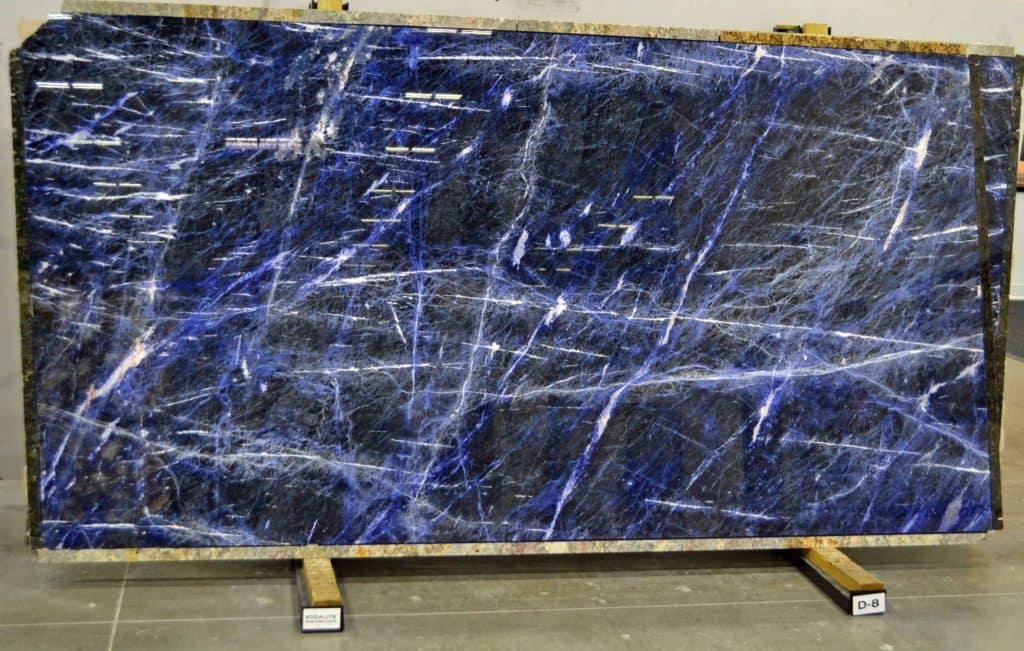

- Be cautious of viewing samples of natural stone. Small samples are rarely representative of a full slab. It is recommended to view the full slab or ask to view a photo of the full slab that would be used prior to purchasing.

- Slabs will often have surface imperfections such as fissures, pits, lines, and color variations. That’s normal and expected. It’s actually part of natural stone’s charm.

- Ask about how often a natural stone will need to be sealed. Generally, it will be sealed before or during installation and then will need to be reapplied periodically.

- When looking at Engineered Stone (Quartz)

- Quartz is man-made and is made up of tiny quartz crystals compressed together, making these slabs very durable. It’s also non-porous so it doesn’t need to be sealed.

- There are many different manufacturers with their own sets of colors so check with your fabricator to see which brands they offer.

- Quartz is recommended for customers who prefer the white colors or patterns found in marble without the extra maintenance of natural stone.

- When looking at Natural Stones…

- Make a few selections and ask the fabricator for quotes on each. Every fabricator will have their own pricing structure that depends on the material (every stone and quartz color will have a different price point), type and number of sink cutouts, linear feet of edging, backsplash, total square footage, etc. Be sure to ask how your fabricator charges for materials.

Step 3: Schedule and Install

- Talk with your fabricator about the lead time they’ll need for scheduling as they can be booked out for weeks or months. Having this discussion early makes planning much easier. We recommend that people select/order their countertops about the same time they order their cabinets.

- Sign any paperwork required and pay the deposit. Fabricators often require a deposit to purchase slabs, place inventory on hold, and hold a spot in their schedule for your project.

- Schedule a date for your fabricator to make an official template of your cabinets and a date for them to come to install.

- Provide any information they need before the template date. Usually, shops will need to know the model numbers for sinks, faucets, and ranges/cooktops.

- If you are using existing cabinetry, be sure to check who is responsible for removing the old countertops. Fabricators usually do not do this. It’s also a good time to make sure that any supports or other requirements will be installed before the countertop install date.

- Make sure you or a trusted contractor that is familiar with the project will be on-site to answer questions.

- Communicate! Fabricators are happy to help and offer advice through any changes. It’s very common for things to change between a quote and templating. Even small details can cause larger issues if they’re not communicated. Stay in touch and a good fabricator will do their best to accommodate the changes.

Step 4: Enjoy your new countertops!

A well-installed countertop will be a feature in your home for decades. Enjoy all your hard work and remember to properly maintain them to keep them looking great. Here at Slabworks of Montana, we love to hear how our clients feel about their new countertops so feel free to contact us or leave a review.

We hope this countertop buying guide has helped take some of the confusion out of the process. If you have any questions we’re happy to help!